- HOME >

- Technical Memo >

- Trend and issues with low-Ag flux-cored wire solder

Trend and issues with low-Ag flux-cored wire solder

2013.1.20

As the use of Sn3.0Ag0.5Cu solder to replace the conventional SnPb becomes more common due in part to a recommendation by JEITA, most users designate this alloy type of flux-cored wire solder.

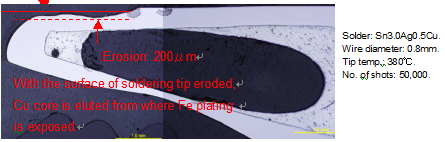

However, changes in the recent economic environment and widespread of Sn3.0Ag0.5Cu solder usage have exposed two major concerns. One is the shift in demand to low-Ag containing materials caused by increased material cost, such as tin and silver. Another is characteristics of the lead-free solder that erode base materials, which leads to disappearance of finer copper lines and accelerated consumption of soldering bit (Fig. 1). Measures against the issues need to be taken.

In this article, the trend with low-Ag solder and the response in the industry are discussed.

Fig.1 Cross section: soldering bit after 50,000 shots

<To read the full text of this article, please send a request from the “Form” button below.>

Index

Index Domestic Bases

Domestic Bases Overseas Bases

Overseas Bases Sales Network

Sales Network Index

Index Message

Message Description of Business

Description of Business Overview

Overview History

History CSR

CSR