- HOME >

- Search Products >

- Solder Paste >

- SB6NX58-M500SI

SB6NX58-M500SI

Sn 3.5Ag 0.5Bi 6.0In 0.8Cu

Excellent Durability Against Heat Cycle Stress

Ideal for extreme environments

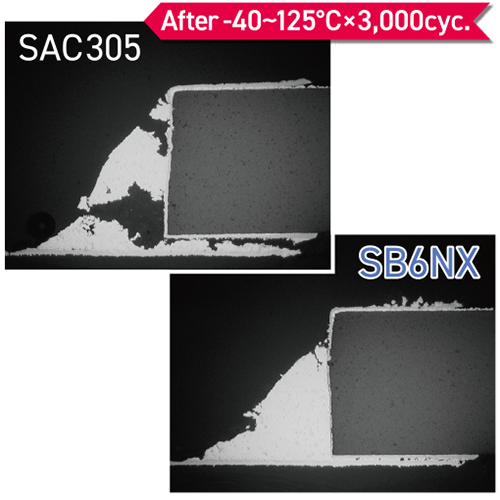

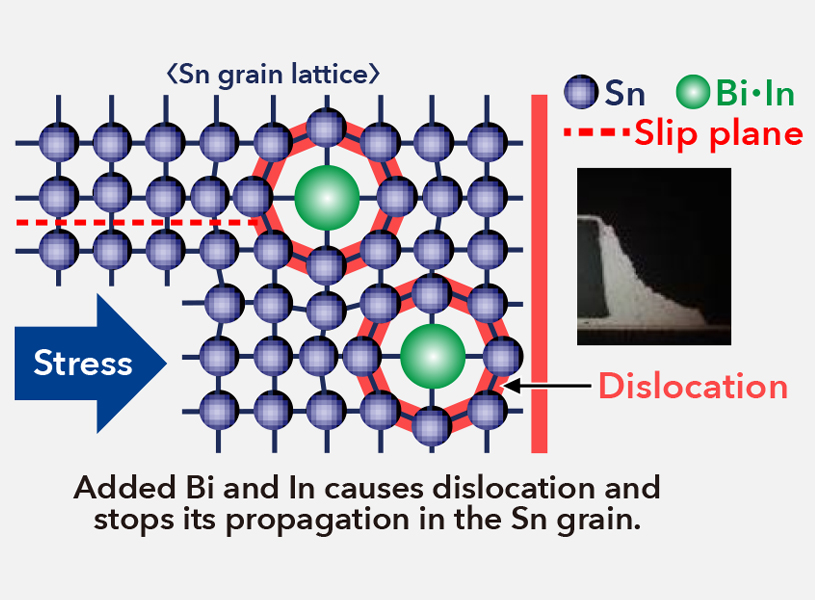

SAC type solder joint cannot comply with longer product life requirement for such application that are exposed to significant higher temperatures. To make a much stronger, fatigue resistant joint possible, solid solution strengthening of Sn crystal lattice is facilitated by addition of In and Bi.

■Elements (Bi,In) added

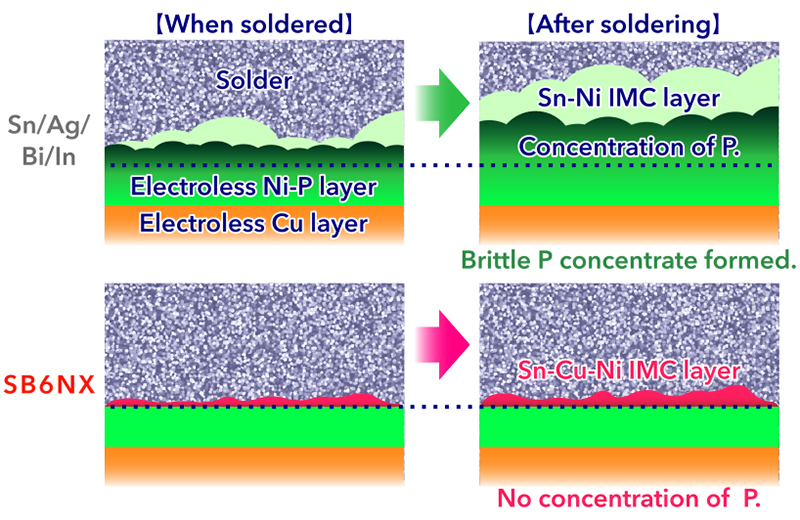

Recommended for ENIG finish

In ENIG finish, Sn-Ni IMC layer thickens and along with concentration of P causes the joint interface brittle.By adding Ni-compatible Cu, SB6NX forms a Ni barrier layer and effectively prevents the thickening of Sn-Ni IMC layer, realizing high joint reliability with ENIG finish.

■Effect of added Cu

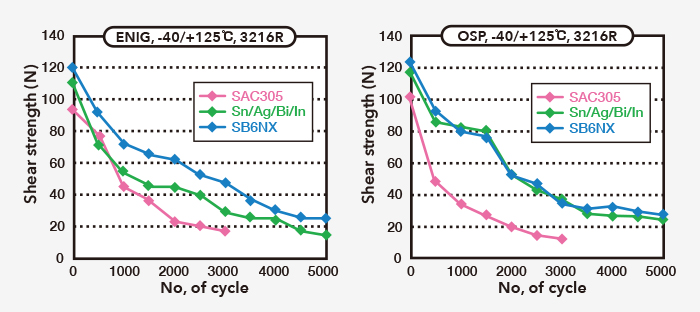

For the better joint reliability

In comparison with SAC305, SB6NX has better elongation property and is less prone to deformation. That helps to prevent propagation of crack at the solder joint in thermal cycling. As found below, SB6NX shows much higher sheer strength than SAC305 with ENIG and OSP substrate alike.

■Stress strength after T/C

Product Performance Table

- Product Name

- SB6NX58-M500SI

- Product Category

- Solder Paste

- Composition

- Sn 3.5Ag 0.5Bi 6.0In 0.8Cu

- Melting Point(℃)

- 202 - 204

- Particle Size(μm)

- 20-38

- Viscosity(Pa.s)

- 200 / 120( for Dispense)

- Flux Content(%)

- 11.0 / 13.0( for Dispense)

- Halide content(%)

- 0

- Flux Type

- ROL0 (IPC J-STD-004A)

- Characteristics

- for Dispense:SB6NX58-M500SID

Index

Index Domestic Bases

Domestic Bases Overseas Bases

Overseas Bases Sales Network

Sales Network Index

Index Message

Message Description of Business

Description of Business Overview

Overview History

History CSR

CSR