- HOME >

- Search Products >

- Heat Curable SMT Adhesive >

- JU-R4S

JU-R4S

Best suited for keeping large

components from falling off

during double-sided reflow

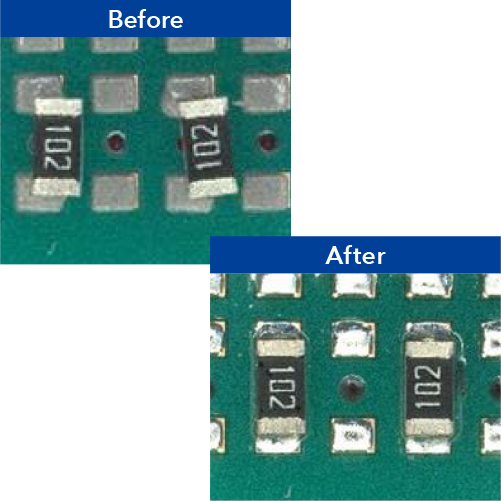

Helps keep components on the board from

falling, shifting, or floating during reflow

Using a conventional adhesive with solder paste can result in the

lifting of components during reflow because the adhesive cures

before the solder paste melts. JU-R4S maintains its fluidity while

the solder is molten and facilitates setting of the components.

Allows solder paste

self-alignment at reflow

JU-R4S is designed to commence curing after the solder

(SAC305) has melted. Therefore, JU-R4S does not hinder

self-alignment of components that may occur when the

solder has melted.

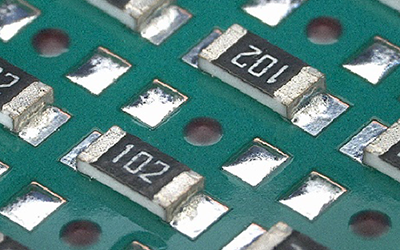

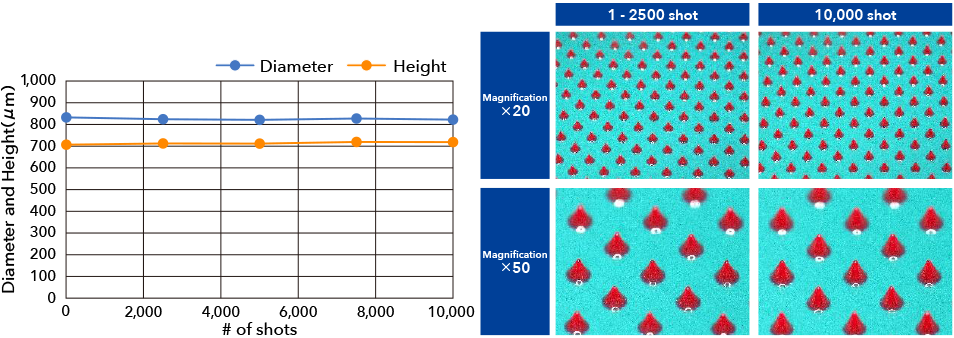

Stable dispense shape and superior electrical reliability after curing

Dispensability of JU-R4S was improved by reducing the viscosity

while shape retention was also improved by optimizing the TI value.

The resultant tall deposits ensure contact and adhesion even for tall components.

Nozzle: 19G single Dispense pressure: 350kPa Dispense time: 60msec

Clearance height: 280um Syringe temp.: 33℃

Product Performance Table

- Product Name

- JU-R4S

- Product Category

- Heat Curable SMT Adhesive

- Composition

- Epoxy resin

- State / Color

- Paste, red

- Viscosity(Pa.s)

- 50

- Tg(℃)

- 59.5℃

- Shelf life (0-10℃)

- 6 month

Index

Index Domestic Bases

Domestic Bases Overseas Bases

Overseas Bases Sales Network

Sales Network Index

Index Message

Message Description of Business

Description of Business Overview

Overview History

History CSR

CSR